A Test of Strength

Every pipe and tube shipped from MST is Eddy Current tested to ensure it’s the high-quality product we promise. Tried, true and reliable, Eddy Current testing has been performed since World War II, and it’s still the gold standard. This nondestructive technique deftly detects imperfections using electromagnetic induction and tests for cracking, corrosion, pitting and thinning.

Protect your tube and pipe projects as well as your reputation, and don’t settle for hydrostatic pressure testing that simply cannot perform the same rigorous testing as Eddy Current.

Why Eddy Current?

- Sensitive to both surface and subsurface imperfections

- Capable of detecting imperfections through multilayered structures

- Able to detect through thin non-conductive surface coating

- Conducted full-body 360 degrees around the pipe or tube

- Conducted with very little pre-cleaning

- Nondestructive and reliable

- 4-8 times more sensitive than hydro

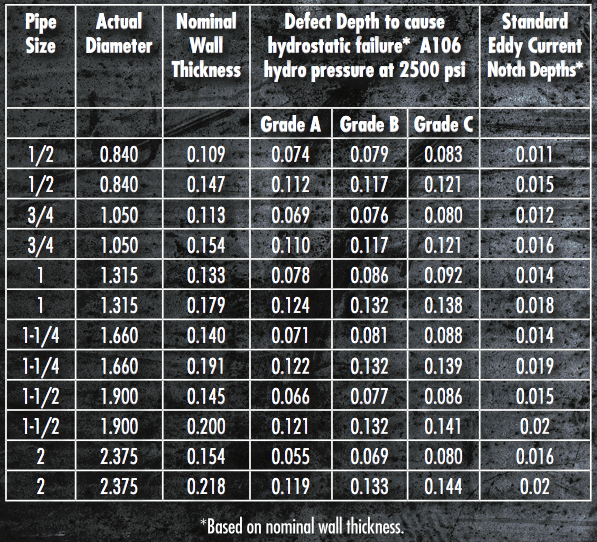

Eddy Current Testing Specifications

Eddy Current Testing for A106 Pressure Pipe

For a portable piece that explains Eddy Current Testing on A106 Pipe, its advantages and specifications, download our Eddy Current v. Hydrostatic Testing informational piece.

Why say no to hydro?

The antiquated hydrostatic pressure test is designed to uncover leaks in pressure vessels. That’s simply not enough to thoroughly measure the integrity and strength of your pressure pipe. Pipelines, plumbing, gas cylinders, boilers and fuel tanks need pipe that has been through comprehensive, nondestructive testing to ensure it’s strong, safe and reliable. Although there have been zero hydro failures at MST, your pipe products still require the rigorous testing that just can’t be done with hydro. Your pipe products – and your reputation – require Eddy Testing.

Want to learn more?

If you still have questions about the benefits of Eddy Current Testing or want to learn more about any of our tube and pipe products, we’re happy to help. Simply fill out the form, and we’ll get back with you quickly.