Precision in every step of the process

Every seamless tube and pipe manufactured by MST is cold drawn (cold finished) to our customers’ exact specifications. Each order goes through a series of precise steps and thorough testing in our state-of-the-art facility before being shipped on time, every time.

- Raw material in a broad selection of grades and sizes arrives at our state-of-the-art facility as solid, round billets.

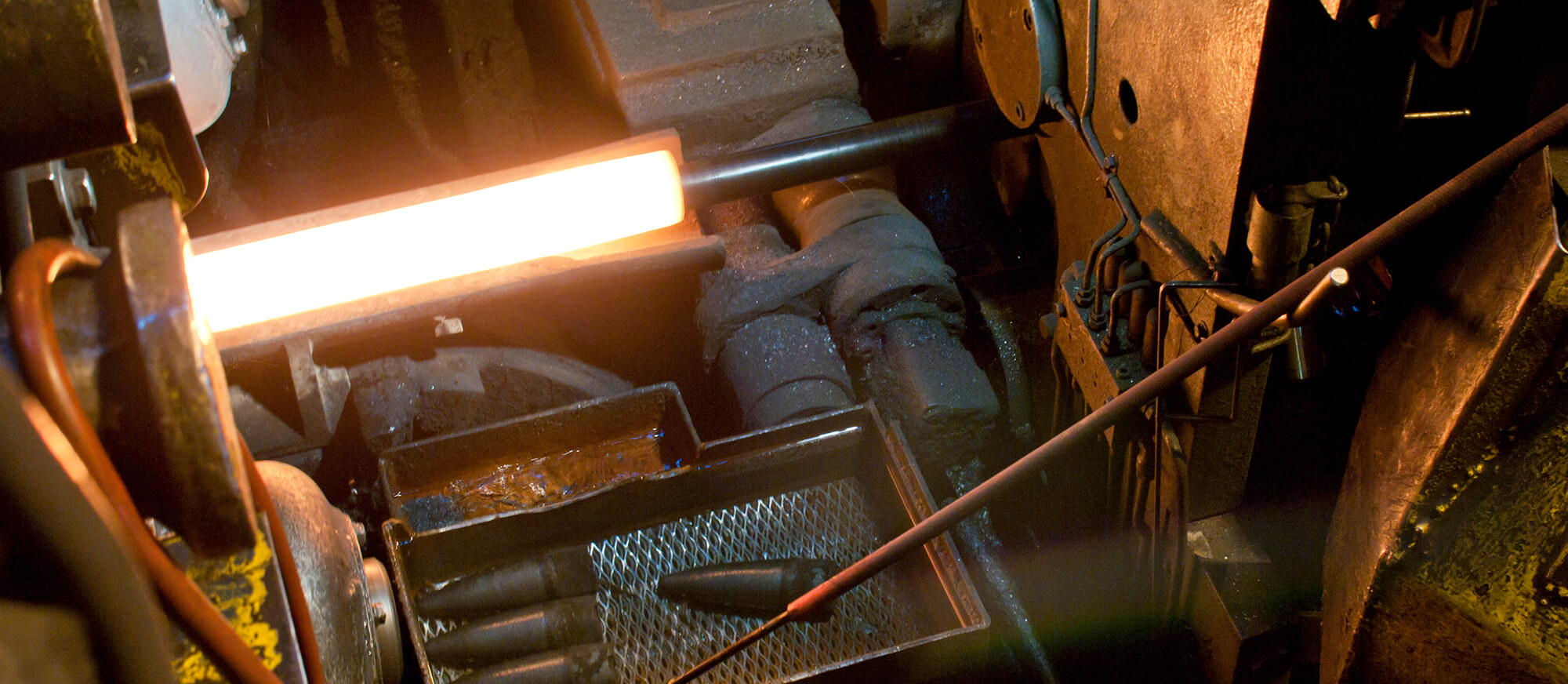

- Each billet is heated in a rotary hearth furnace and indented in the exact center.

- The billet enters the rotary piercing mill where a pneumatic ram feeds the billet between heavy rollers that drive it over a piercing point, producing a tube hollow.

- While still hot, the tubes or pipes are reduced in size in a stretch reducing mill, which produces shells.

- After cooling, the shell is either cold worked on a draw bench, which pulls it through the stationary die and over a mandrel, or on a cold pilger mill, which cold reduces it by driving the shell over a tapered mandrel and through rotating dies. These processes both improve grain structure and surface condition; increase hardness; and reduce the product to the desired size and thickness within extremely close tolerances.

- When cold working is complete, each piece moves to the annealing furnace, where variations of temperature, time and number of cycles produce a wide range of hardness and tensile strength to meet the industry standards as well as customer specifications and requirements.

- Once straightened to desired tolerances, the product is cut to length.

- To ensure quality, the product is tested by eddy current and, if desired, by ultrasonic and/or hydrostatic test.

- Samples are cut per order and specification and then moved to our metallurgic laboratory for testing.

- A certified material test report is then generated for each order and the final products are packaged in bare bundles with metal straps for shipping.

- Cold-drawn tubes and pipes – which have received minimal handling to ensure excellent surface finish – are shipped.

- Tubes arrive at their destination – on time, every time.

Want to learn more?

If you have questions about specific products or want to know more about our process, we’re happy to help. Please complete the form and we’ll get back with you right away.